In today’s competitive market, achieving sustainable growth requires a strategic approach. Lean strategy helps maximize customer value and optimize efficiency. This versatile lean thinking methodology, rooted in lean manufacturing principles, offers a powerful framework for success across various sectors.

Table of Contents:

What is Lean Strategy?

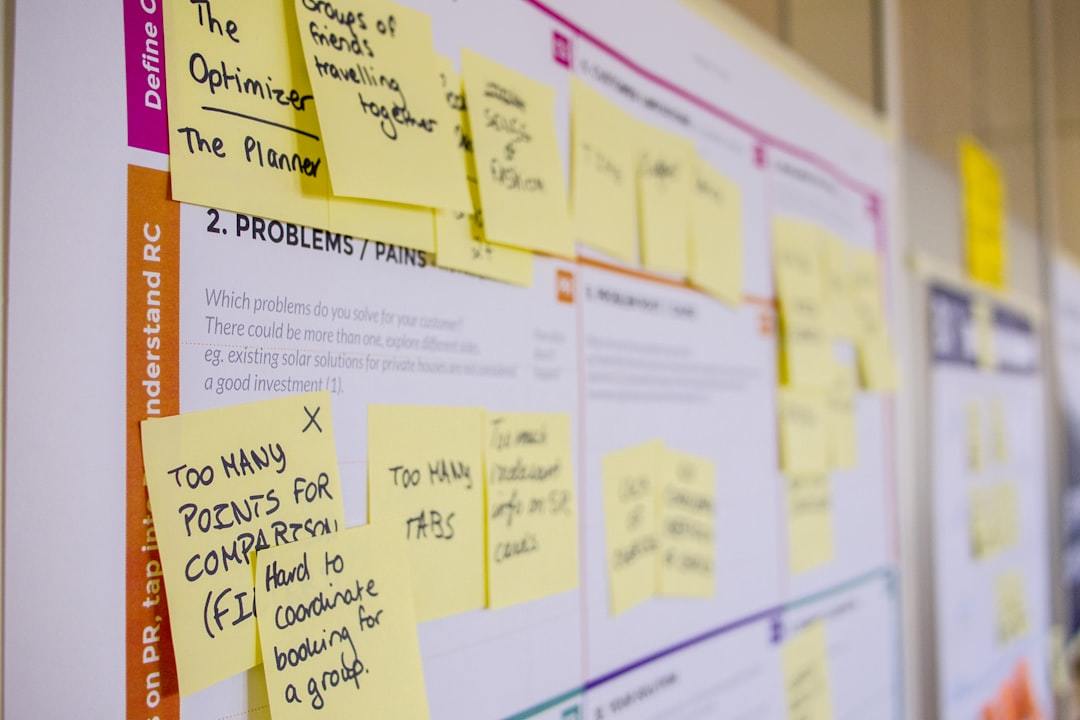

Lean strategy transforms how businesses operate. It involves understanding customer needs and optimizing each step in the value stream. Lean strategy eliminates non-value-added activities to deliver exceptional customer value. It’s not just about cutting costs; it’s about agility, responsiveness, and a customer-centric approach.

The 7 Core Principles of Lean Strategy

Seven core principles underpin the lean strategy. These adaptable principles drive growth and apply to any industry.

- Identify Value: Define value from the customer’s perspective. What are their needs, and what are they willing to pay for?

- Map the Value Stream: Visualize every step in delivering value, from start to finish. This reveals inefficiencies and areas for improvement, making value stream mapping a useful tool.

- Create Flow: Optimize processes for smooth, uninterrupted flow. Eliminate bottlenecks and reduce delays to expedite value delivery.

- Establish Pull: Let customer demand drive production. Implement pull systems where work is initiated only when needed, minimizing overproduction and excess inventory.

- Pursue Perfection: Continuous improvement, or Kaizen, is central to lean strategy. Regularly assess processes and make incremental changes. Even marginal gains from these business principles lead to significant improvements over time.

- Respect People: Foster collaboration where all employees contribute to improvement initiatives. Respect ensures engagement, which is vital for lean strategy.

- Create Knowledge: A lean strategy requires ongoing learning. Continuously seek new knowledge, capture lessons, and share best practices. A permanent knowledge repository is key for maintaining continuous improvement and spreading good ideas across the business.

Lean Strategy Deployment: Putting Principles into Action

Implementing a lean strategy is a collaborative effort. Leaders translate strategic goals into actionable daily tasks.

Begin with a SWOT analysis to understand strengths, weaknesses, opportunities, and threats. This aligns your mission, vision, and long-term goals with lean principles. Aligning the executive team around objectives is crucial, as they often employ hoshin kanri and incorporate Kainexus for customized solutions.

Communicate the “why” behind the change and encourage employee feedback. Visibility promotes transparency into how each person contributes. Empower teams to identify and own improvement areas. Lean strategy deployment translates goals into daily actions. The Harvard Business Review discusses similar strategy concepts. Regular improvement work builds future resilience, anticipating change. Consistent processes also create visibility.

for teams to implement. Lean business management is critical in a production planning atmosphere where the team might have limited resources. Applying Lean Strategy Deployment, known as Hoshin Kanri,Daily huddles using Hoshin planning are a powerful strategy to implement with teams. Lean business management is critical in a production planning atmosphere where the team might have limited resources. Applying Lean Strategy Deployment, known as Hoshin Kanri helps. The strategy sets a clear direction for improvement work.

Case Study: Lean in Action

A software company faced long project timelines and numerous bugs, which impacted its reputation. Value stream mapping revealed non-value-added tasks, like excessive documentation. These bureaucratic procedures actually hindered knowledge sharing and delayed project implementation.

Streamlining the workflow eliminated unnecessary bureaucracy. Collaboration organized projects through regular communication and visibility, promoting transparency across all aspects of the projects. Teams collaborated through daily huddles. The strategy of accessing lean experts proved invaluable. Incorporate Kainexus into your deliberate strategy.

| Before Lean | After Lean |

|---|---|

| Lengthy project timelines | Reduced time-to-market |

| Excessive bugs & rework | Significant decrease in error rate |

| Bureaucratic procedures | Streamlined workflows |

Conclusion

Lean strategy empowers organizations to embrace continuous improvement. It streamlines processes and eliminates waste to improve performance. It prioritizes customer-centric value delivery, resulting in sustainable growth.

By committing to core lean principles, businesses improve financial performance and organizational strength, creating future opportunities. A dedicated customer success manager committed to best-in-class response helps facilitate this lean transformation. Lean strategy deployment and sharing spread good ideas for business improvement are effective means for businesses of any size. Leverage Kainexus to access lean experts.

, consistent processes can be establishedLeadership commitment, collaboration, and employee involvement are essential for implementing a lean strategy and achieving lasting improvements across all metrics. With dedicated customer success, a permanent knowledge repository, and standardization establish consistent processes. Spread improvement across your team and stay focused on your core mission, and company builders can adopt a lean strategy to consider viable opportunities within their businesses.

Subscribe to my LEAN 360 newsletter to learn more about startup insights.